-

Mr. FuHow to solve the problem of accurate testing of miniature HF tags

NFC, asset management, embedded and other applications, spawned a large number of small size RFID tags, such as the diameter of less than 10mm, length and width of 5mm or even about 3mm special tags. So how to solve the problem of accurate testing of tiny HF tags?

On the spot, Mr. Fu mindi, deputy general manager of RealSmart Tech introduced the main test items of micro label performance test. As well as the evaluation of label performance of several important reference elements, and related parameters of the measurement method.

Three important reference elements of label performance: The importance of frequency:

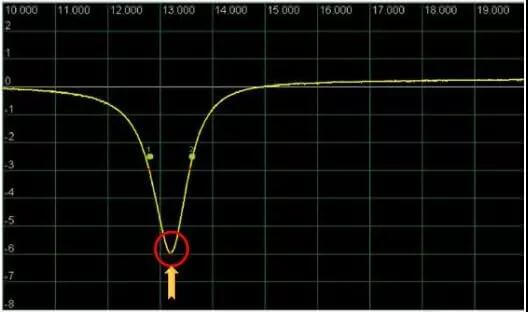

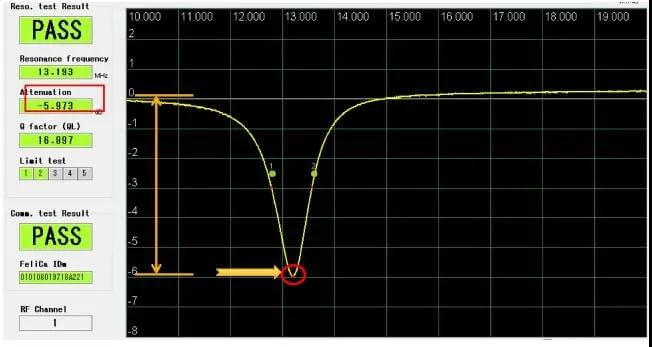

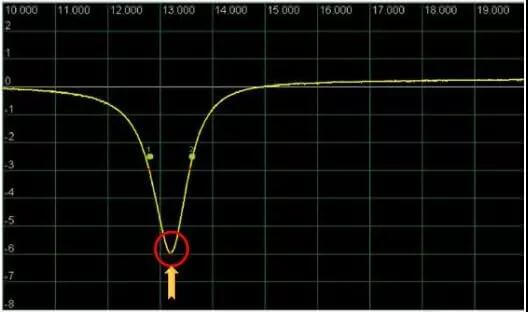

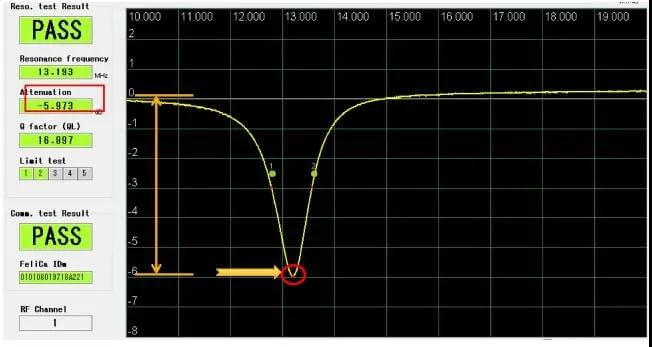

The importance of frequency: Case sharing: TI2048 tag design, conventional antenna design 13.56+/-0.5MHz, customer test samples, poor reading up to 20%. According to the analysis of the client's reading head, it is found that the antenna of the reading head is designed with narrow bandwidth (13.8~14.3M) and high Q value in order to achieve high reading distance. When the product frequency exceeds the antenna bandwidth of the reading head, the read distance drop is very serious. Adjust the antenna frequency, reading good rate increase to 100%!The importance of Q value:

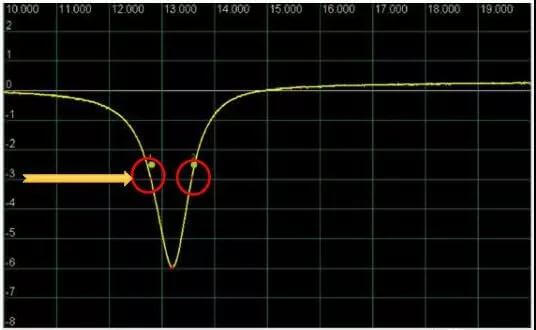

Case sharing: TI2048 tag design, conventional antenna design 13.56+/-0.5MHz, customer test samples, poor reading up to 20%. According to the analysis of the client's reading head, it is found that the antenna of the reading head is designed with narrow bandwidth (13.8~14.3M) and high Q value in order to achieve high reading distance. When the product frequency exceeds the antenna bandwidth of the reading head, the read distance drop is very serious. Adjust the antenna frequency, reading good rate increase to 100%!The importance of Q value: Comparatively speaking, the larger the Q value of similar tags is, the better the reading performance is, because of the higher the Q value of antenna, the smaller the loss is and the higher the efficiency is.The products containing absorbing material is particularly prominent. Designers often find that: the product with absorbing material, although the frequency is within the range of customer requirements, but the distance is not up to the requirements!The importance of antenna attenuation dB value:

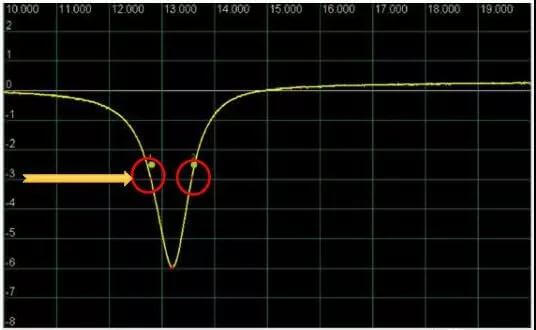

Comparatively speaking, the larger the Q value of similar tags is, the better the reading performance is, because of the higher the Q value of antenna, the smaller the loss is and the higher the efficiency is.The products containing absorbing material is particularly prominent. Designers often find that: the product with absorbing material, although the frequency is within the range of customer requirements, but the distance is not up to the requirements!The importance of antenna attenuation dB value: In order to obtain better read bandwidth, the chip compromises the sensitivity and makes the client read head unreadable in some special application scenarios.In the analysis and test, it can be found that the frequency and Q value test basically do not change much, except that the antenna attenuation dB decreases a lot. At this time, the antenna material needs to be changed to improve the antenna dB value in line with the customer's use.Finally, Mr. Fu analyzed the advantages and disadvantages of conventional test instruments in the market and shared the test equipment T8200PRO-G which is suitable for micro labels.

In order to obtain better read bandwidth, the chip compromises the sensitivity and makes the client read head unreadable in some special application scenarios.In the analysis and test, it can be found that the frequency and Q value test basically do not change much, except that the antenna attenuation dB decreases a lot. At this time, the antenna material needs to be changed to improve the antenna dB value in line with the customer's use.Finally, Mr. Fu analyzed the advantages and disadvantages of conventional test instruments in the market and shared the test equipment T8200PRO-G which is suitable for micro labels.

-

Mr. XuThe share of principle and application of UHF RFID tags detection equipment

Mr. Xu guang, general manager of Beijing XINLI CHUANGDA Information Technology Co., LTD., Shared his personal experience.After three years of struggle, UHF tag detection equipment is very urgent, compared with foreign test products, decided to self-research; Finally, Mr. Xu Shared the principle of frequency sweeping equipment, the function of the product and the future research and development direction.The principle of frequency sweeping equipment:

Mr. Xu guang, general manager of Beijing XINLI CHUANGDA Information Technology Co., LTD., Shared his personal experience.After three years of struggle, UHF tag detection equipment is very urgent, compared with foreign test products, decided to self-research; Finally, Mr. Xu Shared the principle of frequency sweeping equipment, the function of the product and the future research and development direction.The principle of frequency sweeping equipment:

1. Sweep equipment must support relevant protocols, such as iso18000-6c, 6B, 6D, gb, GJB, etc.

2. The power of sweeping equipment is balanced at the corresponding frequency

3. The transmitting and receiving antennas of the frequency sweeping equipment keep almost the same gain and standing wave at the same frequency. If it is not good, it needs to be corrected.

By sticking to the above three points, the minimum starting power of the RFID tags at the corresponding frequency can be obtained to form a curve. The point of the minimum starting power is the resonance point of the current tag antenna.

-

Mr .ChengWhat reliability tests affect the performance of RFID tags

Mr. Cheng mingming, general manager of JUXIN IOT LAB (SHENZHEN) Co., LTD., Shared the necessity of RFID tag testing. Whether the designed label can meet the application requirements requires a series of tests, such as: has the mass production label been tested for consistency? Is aging tested? And so on.Mr. Cheng then Shared the RFID tag testing process, as well as related test items and test equipment.RFID tags testing process:

Mr. Cheng mingming, general manager of JUXIN IOT LAB (SHENZHEN) Co., LTD., Shared the necessity of RFID tag testing. Whether the designed label can meet the application requirements requires a series of tests, such as: has the mass production label been tested for consistency? Is aging tested? And so on.Mr. Cheng then Shared the RFID tag testing process, as well as related test items and test equipment.RFID tags testing process:1. Antenna design and proofing

2. Chip packaging proofing

3. Performance test

4. Strength test

5. Aging test

6. Demo environment test