Nokia's handset business changed hands after a series of strategic missteps in the touch-screen era. However, Nokia is still the world's leading provider of network communication, media technology and intelligent solutions.

Nokia, once a declining traditional mobile phone giant, has found a lot of confidence in the international 5G communication market in recent years, and achieved good results. From 2013 to 2018, Nokia's global patent applications for 5G technology totaled 2,133. Among the telecom network equipment suppliers, the number of patent applications accounted for about 10.5%, ranking the second place. With years of accumulation, acquisition and investment, Nokia has become a Top3 player in 5G market.

Nokia Oulu smart factory

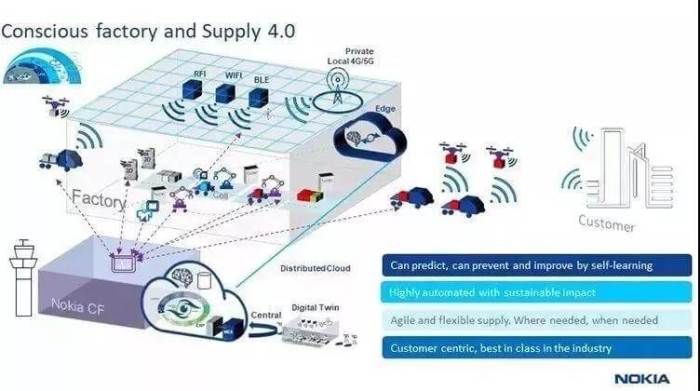

Nokia is heavily invested in 5G research and development, and will naturally be the first to experiment in its own factories. Nokia teamed up with Telia and Intel in March last year to test the first practical industrial application of 5G.In Oulu, a small city near the Arctic Circle, Nokia is building a "factory of the future".

Nokia 5G factory test

The test USES the ultra-low latency and high bandwidth characteristics of 5G technology as well as machine learning technology, aiming to improve the production efficiency of industrial manufacturing

The 5G test network USES Nokia's AirScale, AirFrame and MEC edge computing platforms, as well as Intel?5G mobile test platform and Finwe video analysis application

Through 5G, operators and enterprises will be able to connect more assets and gain new flexibility, as well as more functions such as machine learning, artificial intelligence and widely used automation, thus effectively enhancing operational capacity.

Nokia will continue to use its MEC edge computing platform and Finwe video analytics applications in the Oulu intellisense factory via 4G LTE.The Nokia AirScale platform can be upgraded to 5G through software, an evolutionary path that will help the industry automate more of its business. The 28 GHz band and large-scale MIMO antennas will deliver low latency and bandwidth for high-performance industrial applications.

Nokia's digital transformation

The intellisense factory is one of the practical examples of Nokia's 5G strategy. Nokia has turned the concept into a practical application suitable for the end-to-end supply network, providing complete transparency for every step of the supply chain process.

Currently, the plant USES LTE network technology to provide the low-latency wireless connectivity needed for large-scale industrial automation, and wireless robots to assemble and package base stations.

Nokia Oulu factory on display

In order to make a smooth transition to the wireless future factory, Nokia factory has installed LTE private network covering the whole production area, supporting flexible, safe and high-capacity connection of things in the factory, which is an essential step to build a 5G factory. In addition, Nokia is making some progress in exploring the use of label-based and RFID-based technologies for indoor positioning.